New device could greatly improve speech and image recognition

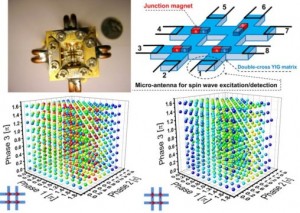

Clockwise, photo of the prototype device; schematic of the eight-terminal magnonic holographic memory prototype; collection of experimental data obtained for two magnonic matrixes.

Researchers at the University of California, Riverside Bourns College of Engineering and the Russian Academy of Sciences have successfully demonstrated pattern recognition using a magnonic holographic memory device, a development that could greatly improve speech and image recognition hardware.

Pattern recognition focuses on finding patterns and regularities in data. The uniqueness of the demonstrated work is that the input patterns are encoded into the phases of the input spin waves.

Spin waves are collective oscillations of spins in magnetic materials. Spin wave devices are advantageous over their optical counterparts because they are more scalable due to a shorter wavelength. Also, spin wave devices are compatible with conventional electronic devices and can be integrated within a chip.

The researchers built a prototype eight-terminal device consisting of a magnetic matrix with micro-antennas to excite and detect the spin waves. Experimental data they collected for several magnonic matrixes show unique output signatures correspond to specific phase patterns. The microantennas allow the researchers to generate and recognize any input phase pattern, a big advantage over existing practices.

Then spin waves propagate through the magnetic matrix and interfere. Some of the input phase patterns produce high output voltage, and other combinations results in a low output voltage, where “high” and “low” are defined regarding the reference voltage (i.e. output is high if the output voltage is higher than 1 millivolt, and low if the voltage is less than 1 millivolt.

It takes about 100 nanoseconds for recognition, which is the time required for spin waves to propagate and to create the interference pattern.

The most appealing property of this approach is that all of the input ports operate in parallel. It takes the same amount of time to recognize patterns (numbers) from 0 to 999, and from 0 to 10,000,000. Potentially, magnonic holographic devices can be fundamentally more efficient than conventional digital circuits.

The work builds upon findings published last year by the researchers, who showed a 2-bit magnonic holographic memory device can recognize the internal magnetic memory states via spin wave superposition. That work was recognized as a top 10 physics breakthrough by Physics World magazine.

“We were excited by that recognition, but the latest research takes this to a new level,” said Alex Khitun, a research professor at UC Riverside, who is the lead researcher on the project. “Now, the device works not only as a memory but also a logic element.”

The latest findings were published in a paper called “Pattern recognition with magnonic holographic memory device” in the journal Applied Physics Letters. In addition to Khitun, authors are Frederick Gertz, a graduate student who works with Khitun at UC Riverside, and A. Kozhevnikov, Y. Filimonov and G. Dudko, all from the Russian Academy of Sciences.

Holography is a technique based on the wave nature of light which allows the use of wave interference between the object beam and the coherent background. It is commonly associated with images being made from light, such as on driver’s licenses or paper currency. However, this is only a narrow field of holography.

Holography has been also recognized as a future data storing technology with unprecedented data storage capacity and ability to write and read a large number of data in a highly parallel manner.

The main challenge associated with magnonic holographic memory is the scaling of the operational wavelength, which requires the development of sub-micrometer scale elements for spin wave generation and detection.

References:http://www.sciencedaily.com/