Rough-and-Tumble Roach Bots Barrel Over Obstacles

Robots inspired by cockroaches can use the shape of their bodies — particularly, their distinctive round shells — to maneuver through dense clutter, which could make them useful in search-and-rescue missions, military reconnaissance and even on farms, according to a new study.

Although many research teams have designed robots that can avoid obstacles, these bots mostly do so by evading stumbling blocks. This avoidance strategy typically uses sensors to map out the environment and powerful computers to plan a safe path around the obstacles.

“This approach has been very successful — for example, Google’s self-driving car,” said lead study author Chen Li, a physicist at the University of California, Berkeley.

“However, it does have limitations,” Li told Live Science. “First, when the terrain becomes densely cluttered — where gaps become comparable to, or even smaller than, robot size — a clear path where robots do not hit obstacles cannot be planned, because obstacles are just too close to each other. Second, this approach requires sophisticated sensors and computers, which are often too large or heavy for small robots to carry around.”

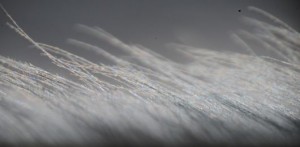

Instead, Li and his colleagues wanted to design robots that did not avoid obstacles, but traversed them. They sought their inspiration from discoid cockroaches, which are about 2 inches (4.9 centimeters) long. These roaches usually live on the floor of tropical rainforests, where they frequently encounter a wide variety of clutter, such as grass, shrubs, leaves, tree trunks and mushrooms.

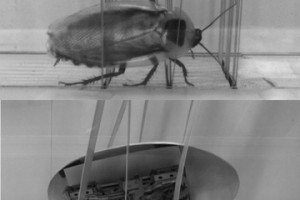

The scientists used high-speed cameras to analyze how the cockroaches moved through artificial obstacle courses with closely spaced, grasslike beams made of card stock. Over the course of hundreds of runs, the insects usually completed the obstacle courses in about 3 seconds. Although the roaches sometimes pushed through the beams or climbed over them, nearly half the time, the insects quickly and effectively slipped past the beams by rolling their bodies to fit through the gaps and using their legs to push off the beams. [See video of the robot cockroach evading obstacles]

Then, the researchers fitted the cockroaches with three artificial shells of different shapes — an oval cone similar to the roaches’ bodies, a flat oval and a flat rectangle — to see what factors influence the insects’ movements. When the glued-on shells made the roaches less round, the insects were less able to perform a roll and maneuver past the obstacles, the researchers found.

Then, the scientists tested a 4-inch-long (10 cm) six-legged robot named VelociRoACH on a similar obstacle course. When it had a rectangular body, the robot had only a 19 percent chance of passing the course, since it frequently got stuck between the grasslike beams. However, when it was fitted with a cockroach-inspired round shell, it had a 93 percent chance of finishing the obstacle course by rolling through the beams, in much the same way real roaches did. This move did not involve any change to the robot’s programming or the addition of any sensors — it was a natural consequence of the shell, the researchers said.

“Robots can take advantage of effective physical interactions with the environment to traverse even densely cluttered obstacles,” Li said.

This research shows how body shapes can help animals and robots traverse terrain, much like how the streamlined body shapes of many birds and fishes (and mimicked by airplanes and submarines) help reduce drag, Li added. “This is why we named this new concept ‘terradynamic streamlining,'” he said.

Terradynamic streamlining may prove especially useful for small, inexpensive robots in applications like search and rescue, precision farming, or military reconnaissance because it allows the bots to traverse obstacles like rubble and vegetation without having to add more sensors and computers, Li said.

“There may well be other body shapes that are good for other purposes, such as climbing up and over obstacles,” Li said. In the future, the researchers plan to analyze how animal and robot body shapes affect other kinds of movement in a variety of environments.

The scientists detailed their findings online June 23 in the journal Bioinspiration & Biomimetics.

References:http://www.livescience.com/